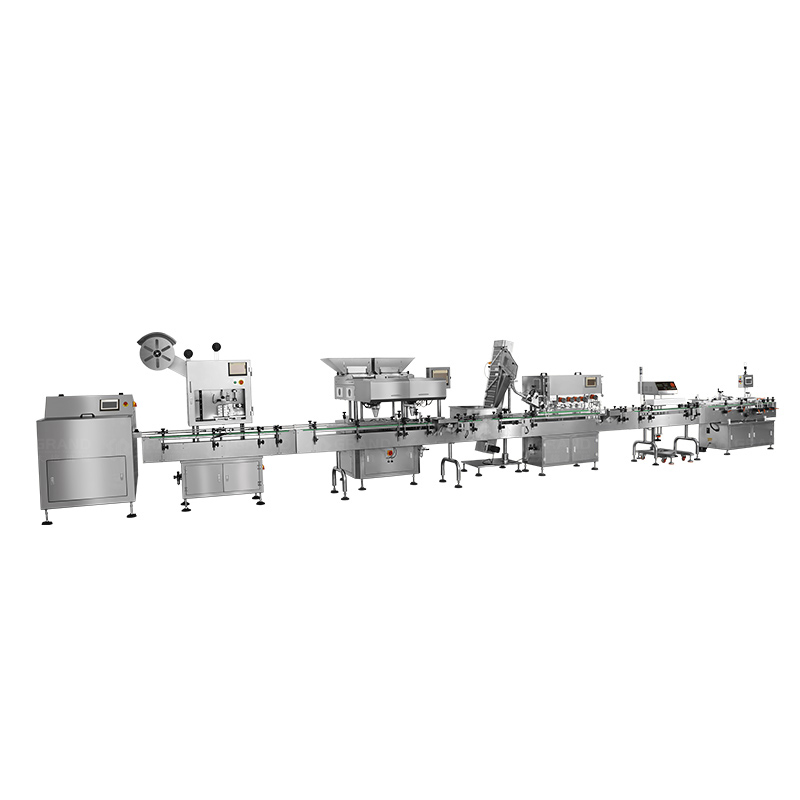

ZC-16TD fully automatic 16-channel electronic counting machine

The bottle blocking device on the bottle feeding track of the bottle conveying mechanism blocks the bottles conveyed by the upper equipment at the bottling position and waits for filling. The drugs enter the medicine warehouse in an orderly manner through the vibration of the feeding corrugated plate. The medicine warehouse is equipped with a counting photoelectric sensor. The drugs falling into the medicine warehouse are quantitatively counted by the photoelectric counting sensor and then loaded into the bottles at the bottling position.

1. Brief description

The bottle blocking device on the bottle feeding track of the bottle conveying mechanism blocks the bottles conveyed by the upper equipment at the bottling position and waits for filling. The drugs enter the medicine warehouse in an orderly manner through the vibration of the feeding corrugated plate. The medicine warehouse is equipped with a counting photoelectric sensor. The drugs falling into the medicine warehouse are quantitatively counted by the photoelectric counting sensor and then loaded into the bottles at the bottling position.

2.Product Features

Strong compatibility, can count and bottle tablets (including special-shaped tablets), capsules, soft capsules (transparent, opaque), pills and other solid preparations or solid particles.

Vibration feeding: 16-channel vibration feeding, unique flap filling mechanism feeding, feeding and discharging are uniform and stable, without damaging the medicine.

High dust resistance: Adopting our company's high dust resistance photoelectric sensing technology, it can work stably under high dust conditions.

Accurate counting: Photoelectric sensor counts automatically, and the bottling error is less than the national standard.

Specially structured nozzle can prevent drug blockage, and small bottle mouths can also be bottled quickly (optional).

High degree of intelligence, with multiple detection and alarm control functions such as no bottle, no counting, fault self-checking, etc.

Function matching: The photoelectric sensor automatically detects and automatically stops the machine when there is no bottle.

Simple operation: Adopting intelligent design, various operating parameters are set according to needs.

Easy maintenance: Operators only need simple training to operate, and disassembly, cleaning and replacement of parts are simple and convenient without tools.

Sealed and dustproof: Configure dust removal box to reduce dust pollution (optional).

3. Main technical parameters

Model

ZC-16TD

Applicable objects

Pills with a diameter of less than 22, compatible with capsules of size 00-5, soft capsules with a diameter of 3.5-diameter 22, plain tablets with special shapes, sugar-coated tablets

Production speed

10-70 bottles/minute

Hopper capacity

about 60L

Power supply

220V/50HZ

Power

0.9KW

Equipment size

1560x1530x1700mm

Gas consumption

0.6Mpa 3.8L/min

Weight

480KG