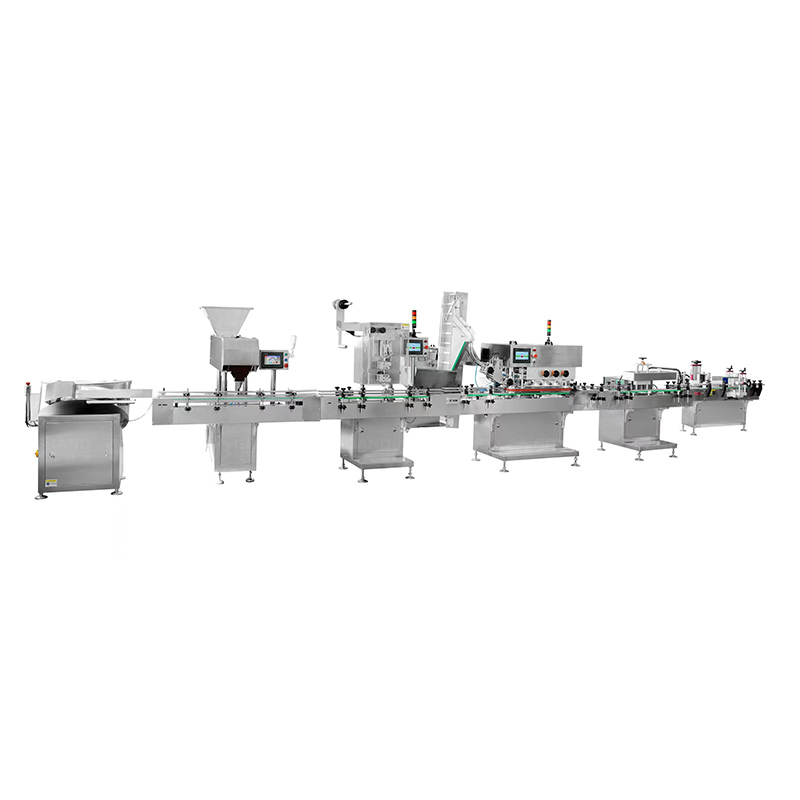

ZC-8TD fully automatic 8-channel electronic counting machine

The bottle blocking device on the bottle feeding track of the conveying bottle mechanism blocks the bottles conveyed by the upper equipment at the bottling position and waits for filling. The medicines enter the medicine warehouse in an orderly manner through the vibration of the feeding corrugated plate. The medicine warehouse is equipped with a counting photoelectric sensor. The medicines falling into the medicine warehouse are quantitatively counted by the photoelectric counting sensor and then loaded into the bottle at the bottling position.

1. Brief description

The bottle blocking device on the bottle feeding track of the conveying bottle mechanism blocks the bottles conveyed by the upper equipment at the bottling position and waits for filling. The medicines enter the medicine warehouse in an orderly manner through the vibration of the feeding corrugated plate. The medicine warehouse is equipped with a counting photoelectric sensor. The medicines falling into the medicine warehouse are quantitatively counted by the photoelectric counting sensor and then loaded into the bottle at the bottling position.

2. Main features

Strong compatibility, can count and bottle solid preparations or solid particles such as tablets (including special-shaped tablets), capsules, soft capsules (transparent, opaque), pills, etc.

Vibration unloading: 8-channel vibration unloading, unique flip plate filling mechanism unloading, uniform and stable unloading, no damage to the medicine.

3. Main technical parameters

|

Model |

ZC-8TD |

|

|

|

Applicable objects |

Pills with a diameter of less than 22, compatible with capsules of size 00-5, soft capsules, plain tablets with a diameter of 3.5-diameter 22, special-shaped tablets, sugar-coated tablets |

|

|

|

Production speed |

10-40 bottles/minute |

Hopper capacity |

about 30L |

|

Power supply |

220V/50HZ |

|

|

|

Power |

0.6KW |

|

|

|

Equipment size |

1360x1530x1700mm |

|

|

|

Gas consumption |

0.6Mpa 3.5L/min |

|

|

|

Weight |

320KG |

|

|