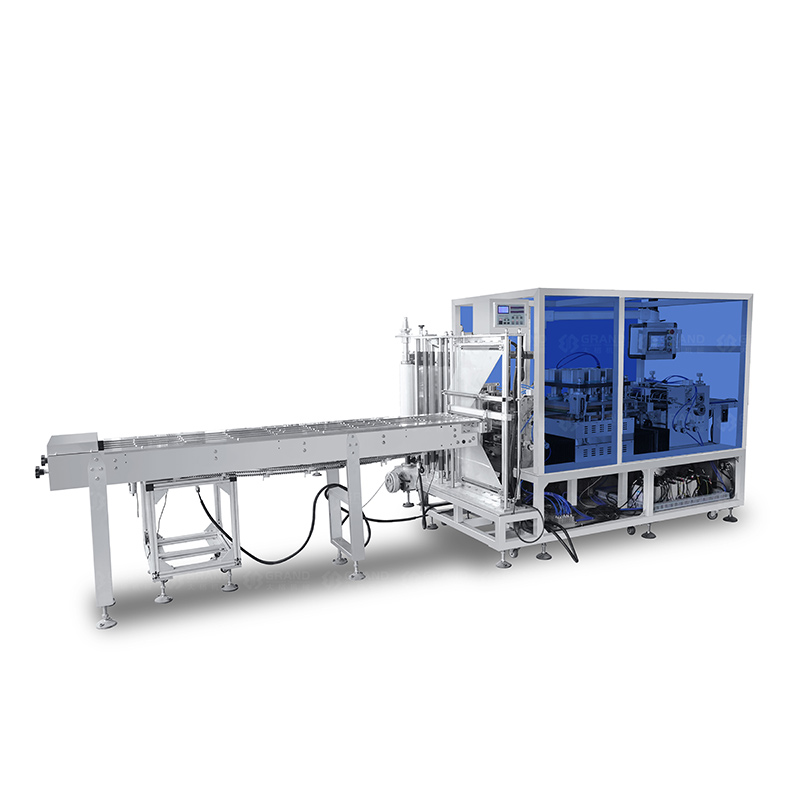

ZH-850PRO Double-sided labeling single roll film four-side sealing packaging machine (standard type)

1、Brief description

This machine adopts PLC motion control processor, temperature module, multi-servo motor, human-machine interface control, highly automated equipment operation, complete functions, large expansion space, and can be customized according to user requirements.

It is suitable for packaging of solid sheet items in the pharmaceutical, health care, chemical, light industry, and food industries such as composite film, aluminum-plastic film, pure aluminum film, aluminum-plated film, and coated paper, such as warm baby, antipyretic patch, infusion heater, analgesic plaster, medical auxiliary material patch, game card, recharge card, pesticide product bag in bag, spicy strip, kiss sticker, temperature measurement sticker, single sanitary napkin and other products.

Optional online batch number barcode printer, syringe, needle automatic feeder, online flexographic printer, visual inspection system.

2、Performance characteristics:

1. The whole machine adopts an open layout structure, modular design station visibility is good, and maintenance and adjustment are convenient. New and safe appearance protection design, safe operation.

2. It has heating plate temperature control detection, main motor overload protection, tension automatic control, packaging material position detection, material storage bin material position detection control, and fault automatic protection shutdown.

3. The enlarged roll film receiving platform and the maximum roll film diameter can reach 400mm, which reduces the equipment downtime and increases the overall practicality of the equipment.

4. Optional horizontal material receiving, with automatic deviation correction roll film automatic tension control mechanism, it is more convenient to change materials.

5. The whole machine adopts reciprocating continuous feeding heat sealing punching and cutting, which is more accurate, faster and more stable.

6. Mechanical heating and sealing: using reciprocating heat sealing mechanism, heat sealing servo control cam drives upper and lower heat pressing (using dot mesh or flat mesh), due to equal stress, the plate is smoother and more beautiful, ensuring the heat sealing pressure between the packaging materials, and ensuring that the packaging bag does not leak or leak. Completely avoid the disadvantages of the previous roller heat sealing structure with loose air leakage.

7. Automatic punching of easy-tear edges and hanging holes makes product packaging more beautiful and classy!

8. This machine is equipped with a German Sik optoelectronic mechanism, which is more accurate and effective for printed packaging materials!

9. Customized multi-channel typesetting methods and special material feeding methods can be customized according to customer product sizes, and automatic special feeding devices can be customized according to customer needs and products.

10. This machine uses domestic and foreign high-end brand PLC motion controllers, high-definition touch screen operation, Chinese and English display, variable frequency speed regulation, servo material conveying, servo traction, servo heat sealing, and servo punching, which can be freely adjusted on the touch screen within a certain range.

11. The finished product output is produced in an orderly manner, and is equipped with a waste collection device, which is convenient for waste collection and energy-saving and environmentally friendly!

12. The whole machine is made of high-quality 304 stainless steel, with high surface treatment technology and outstanding texture, which meets the use standards of the pharmaceutical industry!

13. The whole machine adopts a split connection design, and the host and conveyor can be disassembled for easy mobile installation! It can also be seamlessly connected to the front-end or back-end equipment.

3、 Main technical parameters

|

No. |

Item |

Technical indicators |

|

1 |

Production capacity |

80-300 pages/min (depending on the actual product layout) |

|

2 |

Packaging material (roll Φ75) |

400-840 (widest) XΦ400 mm |

|

|

Suitable materials |

Composite film, coated paper, aluminum film, pure aluminum film, paper-plastic composite film |

|

3 |

Servo motor power |

Traction servo motor 0.75KW 2 pcs |

|

|

|

Heat seal mobile servo motor 1.5KW |

|

|

|

Heat seal upper and lower servo motor 1.3KW |

|

|

|

Easy tearing mobile servo motor 0.75KW |

|

|

|

Product conveying servo motor 0.75KW |

|

|

|

Finished product cutting servo motor 1.5KW |

|

4 |

Heating plate power |

3500w total two |

|

5 |

Power supply, total power |

380V 50Hz 15kw |

|

6 |

Air pump capacity |

≥0.35-0.4m³/min (self-provided) Pressure: 0.6~1Mpa |

|

7 |

Overall dimensions (length x width x height) |

5152 x 1100 (2685 horizontal) x 1800 (middle split transportation, including foot and protective cover height) |

|

8 |

Machine weight Approximately |

2100 kg |