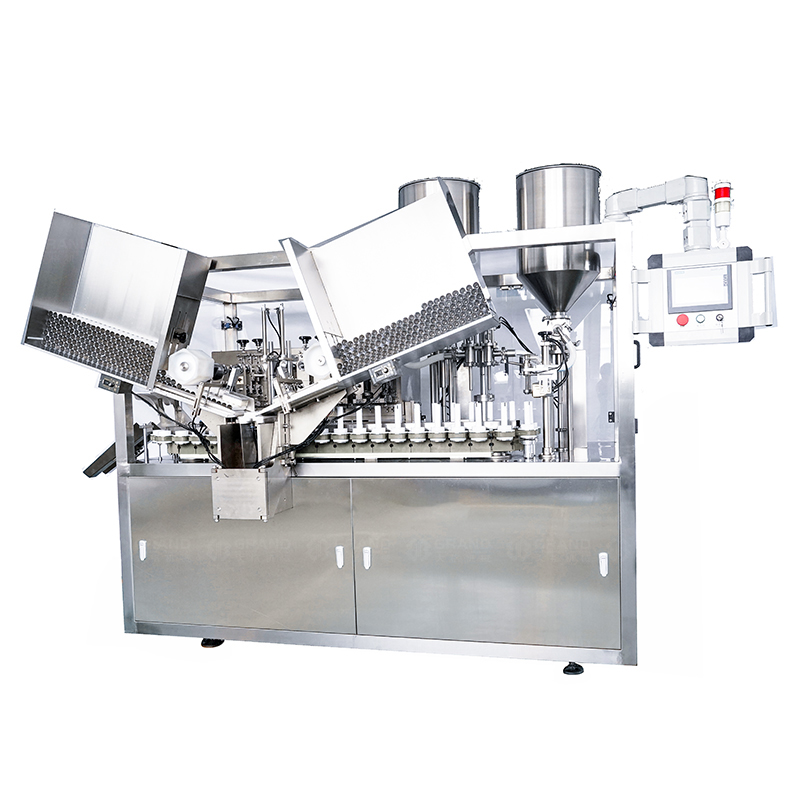

NF-30Z Aluminum Tube Filling and Sealing Machine

NF-30 aluminum tube filling and sealing machine is mainly used for one-time transmission principle. The indexing mechanism is used to drive the turntable equipped with the fixture to make intermittent motion to complete automatic filling and two-side folding, three-side folding and saddle-shaped folding and sealing of the tail.

1. Overview and Application

NF-30 aluminum tube filling and sealing machine is mainly used for one-time transmission principle. The indexing mechanism is used to drive the turntable equipped with the fixture to make intermittent motion to complete automatic filling and two-side folding, three-side folding and saddle-shaped folding and sealing of the tail. The shape and size of the tail can be conveniently and accurately adjusted according to the needs of the user.

The filling measurement is accurate, the folding is stable and adjustable, and the tail appearance is beautiful, neat, firm and hygienic. The trimming is flat. The machine is set with 8 stations. Except for manual tube loading, the rest can be completed automatically. The whole machine runs smoothly and reliably, without noise and other pollution.

All parts of the whole machine that contact the material and some related parts are made of high-quality stainless steel, and the parts that need to be cleaned are all equipped with quick-change devices, which are easy to disassemble and wash. When some materials need to be heated and kept warm, a heating constant temperature device can be installed on the outside of the barrel. All materials that use plastic tubes and composite tubes as packaging materials can be safely selected with this machine. It is the best product for the cosmetics industry, pharmaceutical industry, adhesive industry, shoe polish industry and other related industries.

2. Features

※ The material of the part in contact with the material is 316L stainless steel;

※ The connection of each component is quick-install, which is easy to disassemble and clean;

※ High-quality pneumatic components are used.

※ A blowing device is added at the cutting tail to prevent the cut tail from accumulating on the workbench.

3. Main technical parameters

|

Power supply |

~220V±10% |

|

|

|

Power consumption |

750W |

|

|

|

Filling volume |

0~250 (ml) |

|

|

|

Production capacity |

0~30PCS/min |

|

|

|

Measuring accuracy |

±1% |

|

|

|

Dimensions |

1200X820X1650 (mm) |

|

|

|

Machine weight |

350kg |

|

|

|

Working pressure |

>0.4Mpa750 |

Gas consumption |

0.5 cubic meters per minute |